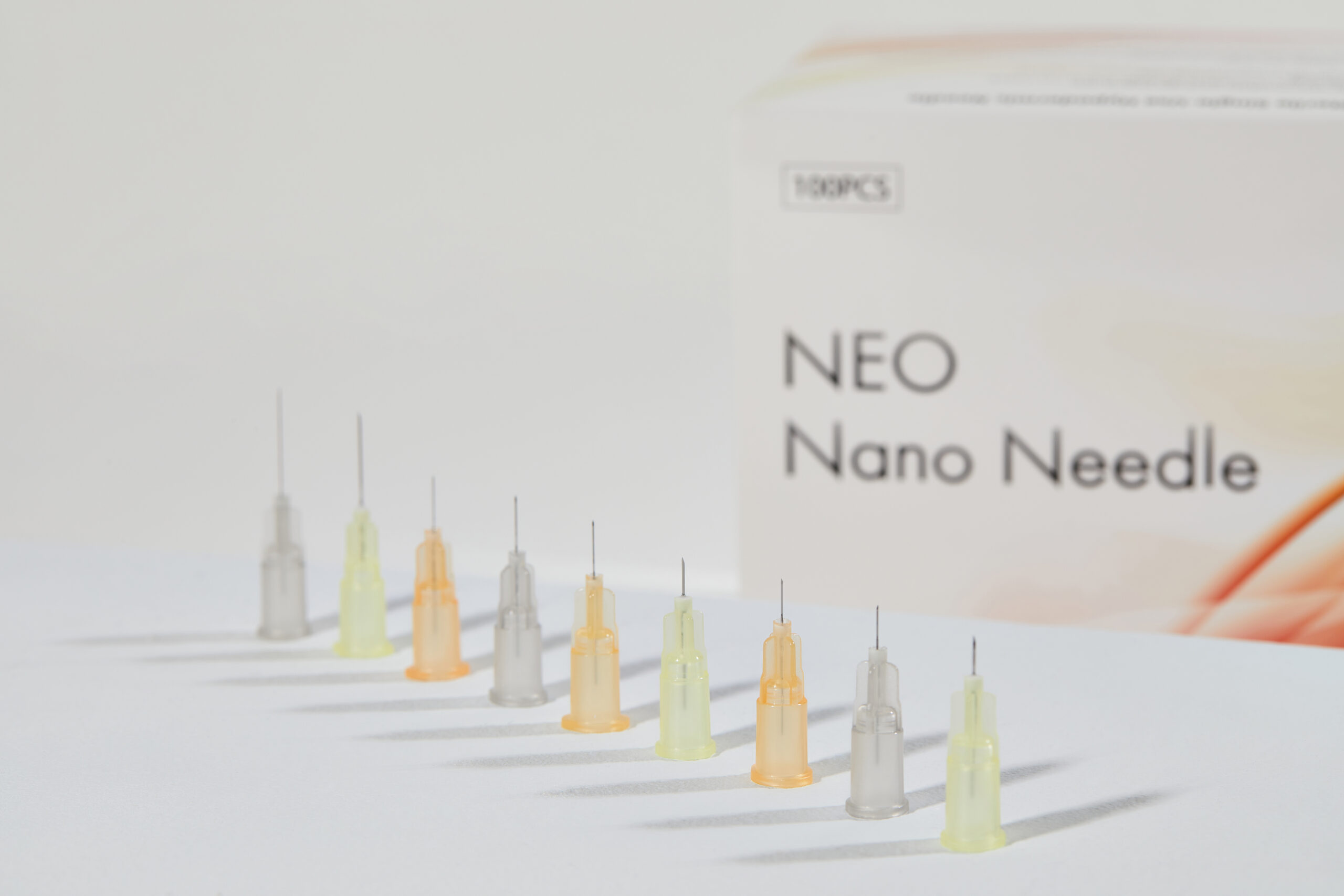

NEO NANO NEEDLE (CANNULA)

₩56,000 – ₩140,000Price range: ₩56,000 through ₩140,000

Flow Fluently

Smooth Surface

Various Size

Medical Safety

Compliant Design

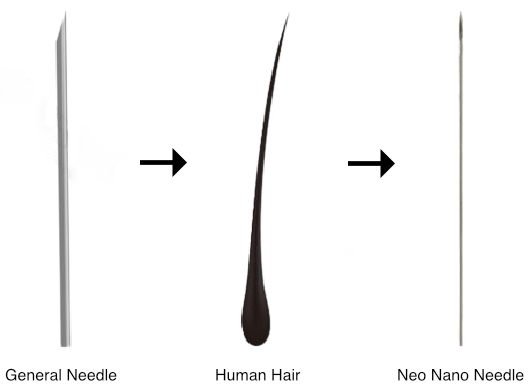

NEO Nano Needles are Thinner than Average Hair

Minimizes Skin Damage and Pain, Enhances Recovery Time from Treatments

Reasons to Use Nano Needle

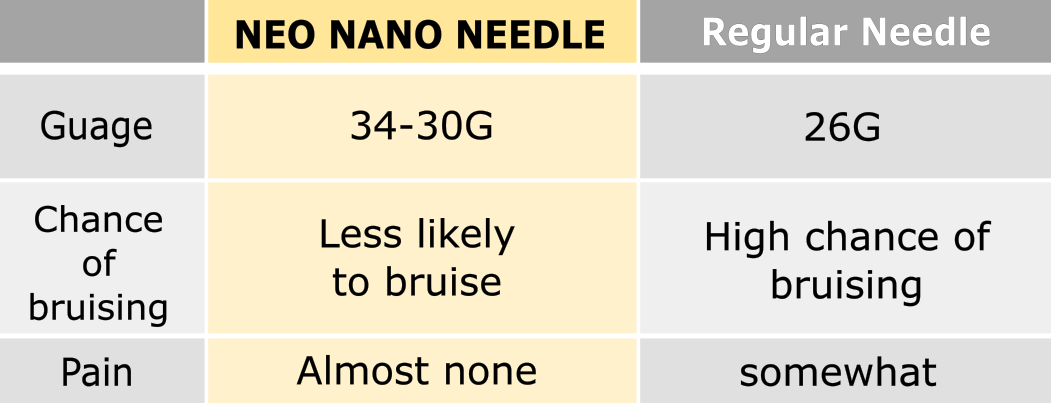

1. Safe Treatment

Side effects such as pain, swelling, erythema, and edema can be avoided.

2. Low Skin Damage

Reduce microbial destruction and cause minimal damage only on the epidermis.

3. Less pain

No resistance and pain of injection to lessen patient discomfort.

4. Precise Treatment

Specific layer of skin and tissue can be accurately targeted for injection.

5. Quick Recovery Period

Minimum bleeding allows for recovery within a day.

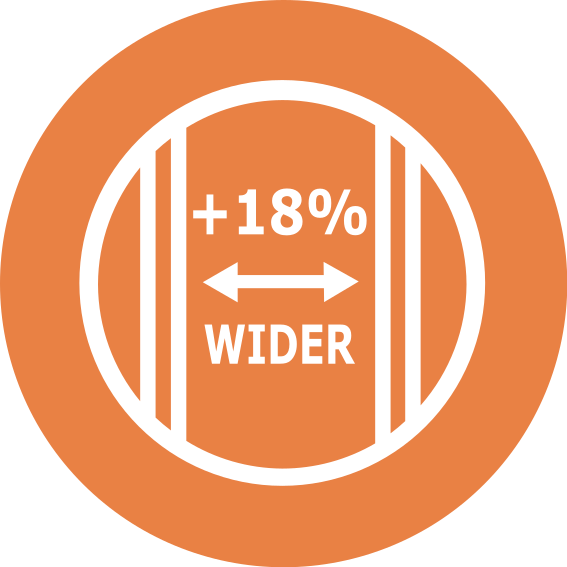

Fluent Flow

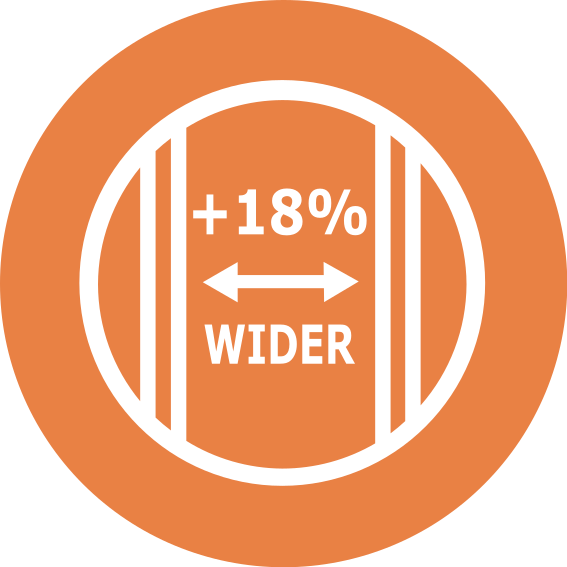

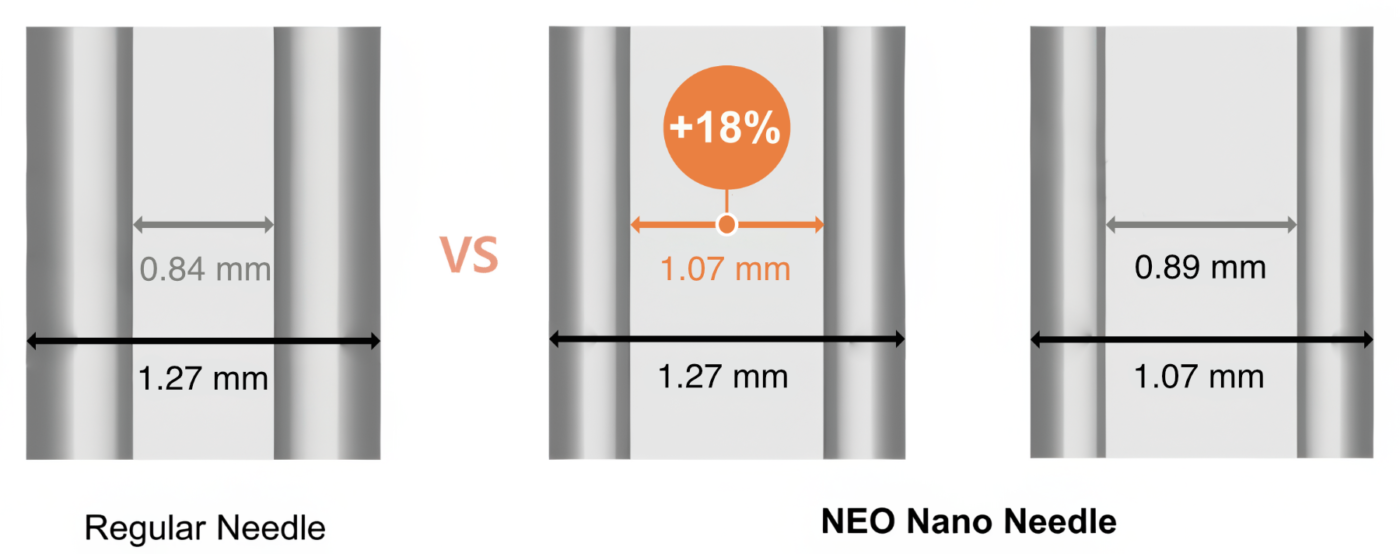

18% Wider Inner Diameter

Non-Toxic Substances

For environment & Public Health

Compliant Design

All in accordance with ISO Standards

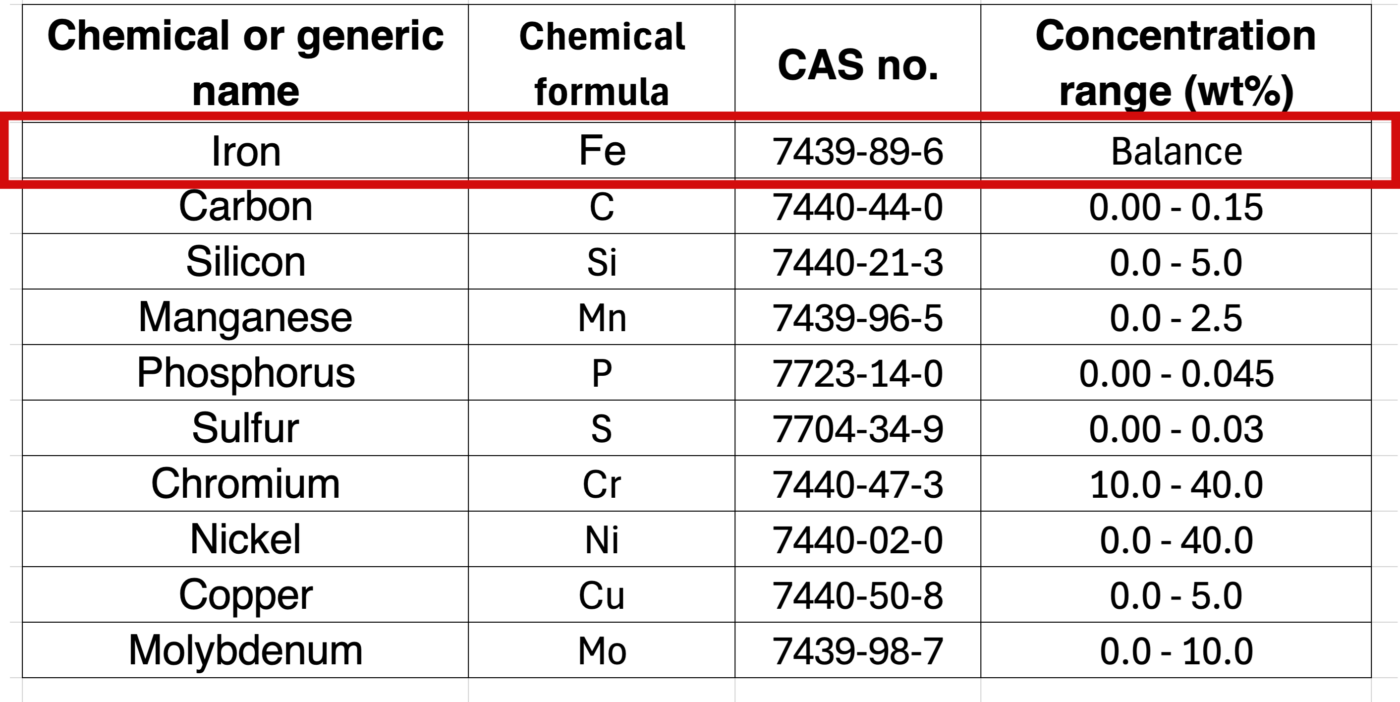

Stainless 304 & Polypropylene

The Most Widely Used for Safety

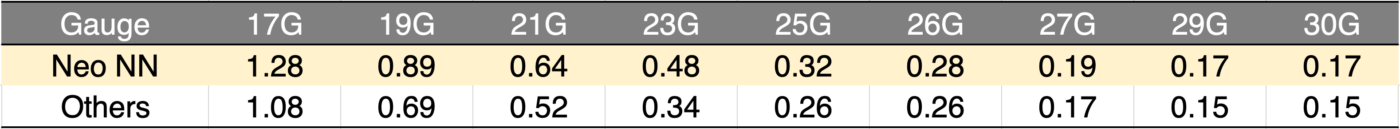

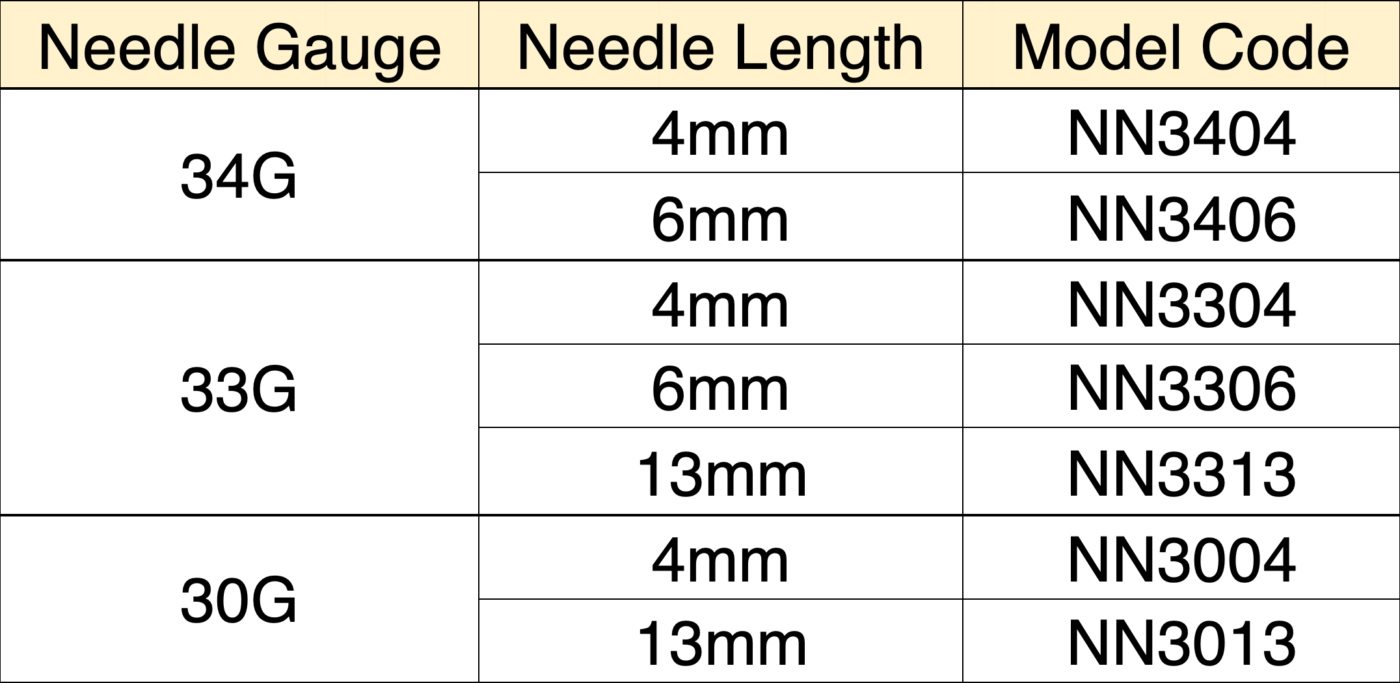

Various Size

28 Models For Various Application

Smooth Inner Surface

Minimize the Damage of Blood Vessel

Chemical-Resistant STS 304 & Polypropylene for Safety

High Quality Materials Ensure Durability and Safety for All Circumstances

Cannula Tube

What is stainless steel?

Stainless steel is made by adding a significant amount of chromium (usually more than 12%) to iron (Fe) to prevent it from rusting.

Among them, STS 304 exhibits excellent properties against high temperature corrosion resistance and creep damage.

Connection Hub

Medical Grade Polypropylene

- Anti-pollution material that does not absorb the solution

- High melting point for durability

- Appearance: granules

- Color: transparent

- Oder: none

- Melting point/range: 150-200 deg. C

- Decomposition temp.: >400 deg.C

- Water solubility: insoluble

- Specific gravity: 1.19-1.23

- Flash point: >450 deg.C

- Auto-ignition temp.: >450 deg.C

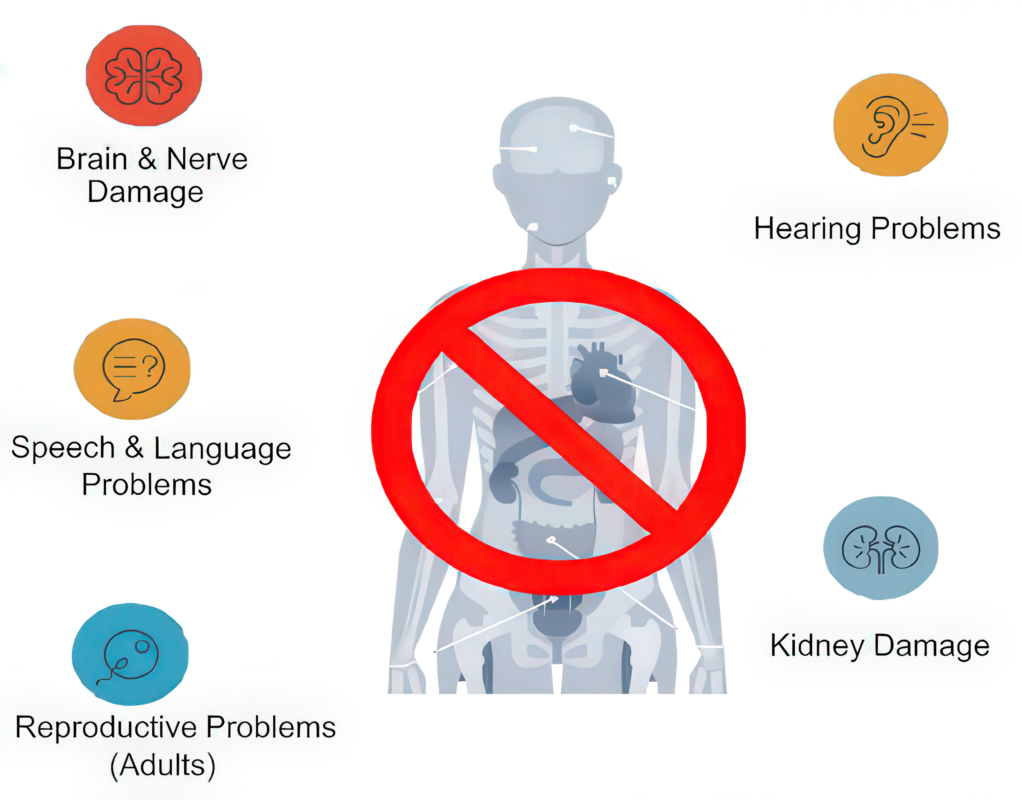

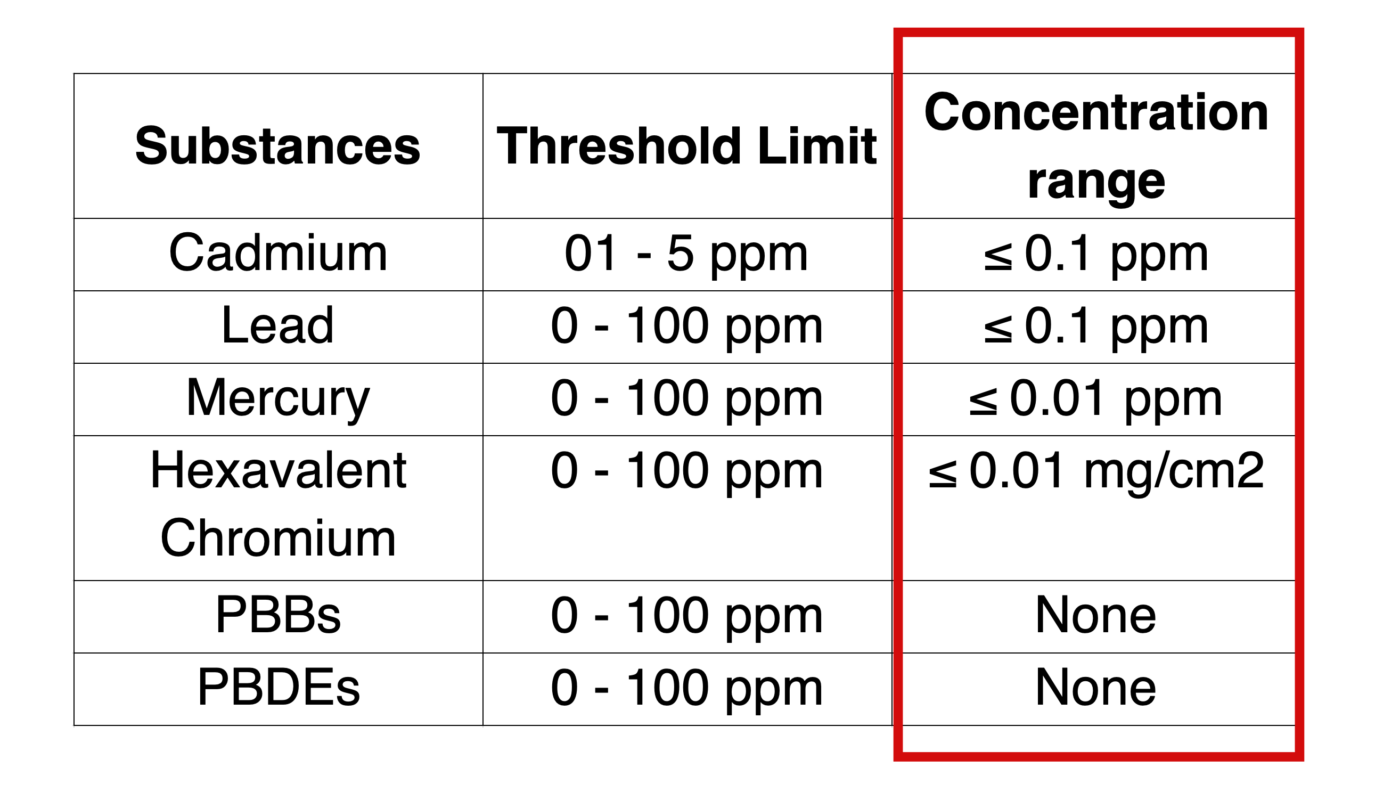

No Toxic Substances were Detected in our STS304

The RoHS Directive Restricts the Use of Ten Substances to Protect Public Health

- Cadmium: Long-term exposure causes diseases such as osteoporosis and idiopathic fractures

- Lead: When exposed to high concentrations of lead, brain-related symptoms such as loss of appetite, dizziness, vomiting, and weight loss appear.

- Mercury: Exposure to high concentrations of mercury vapor can affect the lungs and central nervous system, causing fever, chills, nausea, vomiting, difficulty breathing, and headaches within a few hours.

- Hexavalent chromium Hexavalent chromium: A substance designated as a carcinogen and causes lung cancer when inhaled

- PBBs (polybrominated biphenyls): Endocrine disruptors.

- PBDEs (Polybrominated diphenyl ethers): Environmental hormone-inducing substances.

The Inner Diameter is 18% Wider than Competition

Injectable Solutions can Flow More Smoothly while Maintaining the Needle Gauge

NEO Nano Needles have a larger internal diameter compared to conventional cannulas.

Thanks to the larger internal diameter, the force required to inject filler is significantly reduced, making it possible to work with materials of any density.

Comparison

Wall Thickness & Inner Surface Polishing

Regular Needle

NEO Nano Needle

Not only the outer surface is coated with silicone to minimize friction with the skin but also the inner surface is polished for even smoother solution flow.

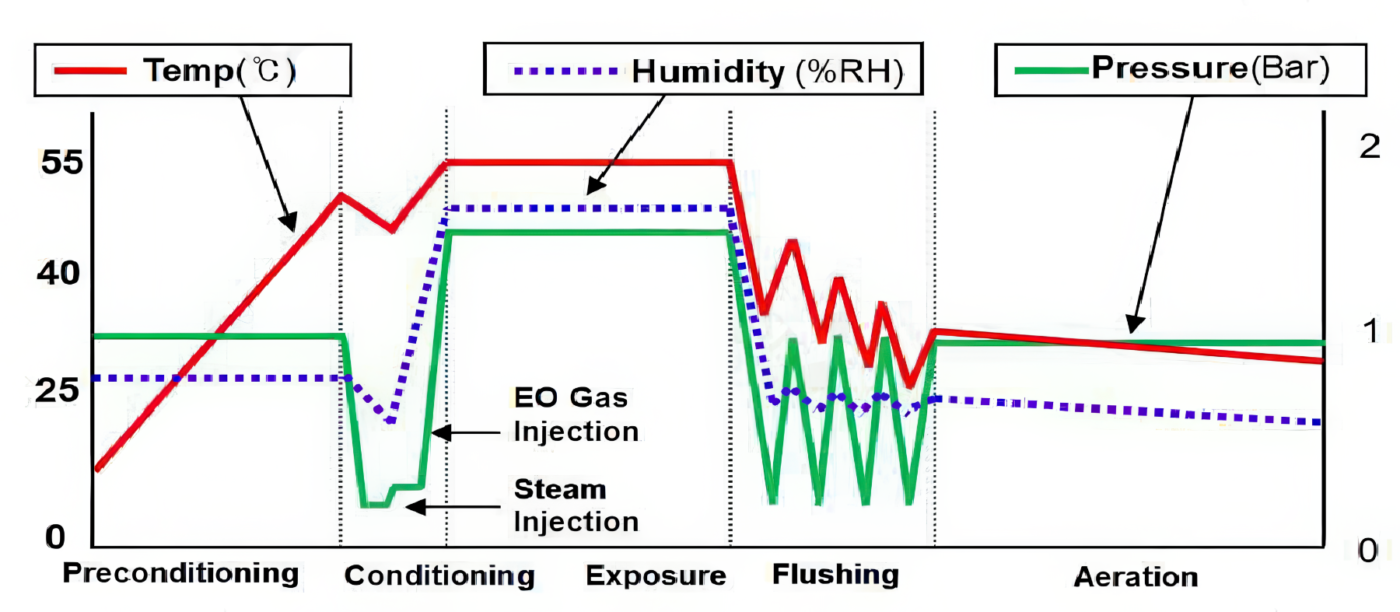

Sterilized up to 12 Hours to Destroy any Microbial Proteins

Controlling the EO Concentration, Temperature, Humidity, and Exposure Time

EO Gas Sterilization

Ethylene Oxide is a colorless gas that is flammable and explosive. The four essential parameters (operational ranges) are:

- Gas concentration (450 to 1200 mg/l);

- Temperature (37 to 63°C);

- Relative humidity (40 to 80%);

- Exposure time (1 to 6 hours).

These influence the effectiveness of EO sterilization.

Within certain limitations, an increase in gas concentration and temperature may shorten the time necessary for achieving sterilization.

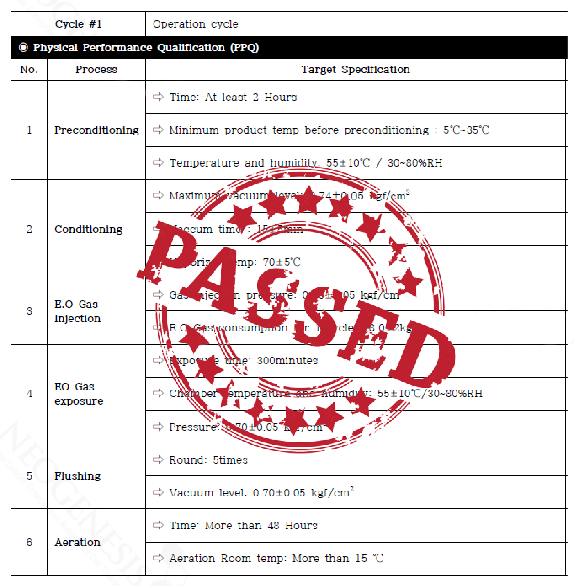

6 Safety Steps of Sterilization are Strictly Managed

Every Aspect of the Product is Analyzed before Final Release

1. Preconditioning:

The step of ensuring that the product has appropriate temperature and humidity by placing it in a controlled space with preset temperature and humidity conditions. (To increase sterilization effect and shorten sterilization time)

2. Conditioning:

- Air Removal: The step of removing air from the sterilizer chamber to reduce the risk of explosion of EO gas and increase the penetration of EO gas

- Steam injection: A step of injecting steam to meet the preset humidity conditions in the sterilizer chamber.

3. EO gas injection:

This is the step of injecting EO gas. When a certain pressure is reached, EO gas injection is stopped.

4. Exposure:

Sterilize the product to be sterilized by exposing it to EO gas for a preset time.

5. Flushing:

- EO gas exhaust and flushing: This is the step of removing EO gas in the sterilization chamber. Inert gas such as nitrogen is created in a vacuum state and filtered air is repeatedly injected to remove EO gas in the chamber.

6. Aeration:

A step of desorbing EO gas remaining in medical devices exposed to EO gas from the medical device.

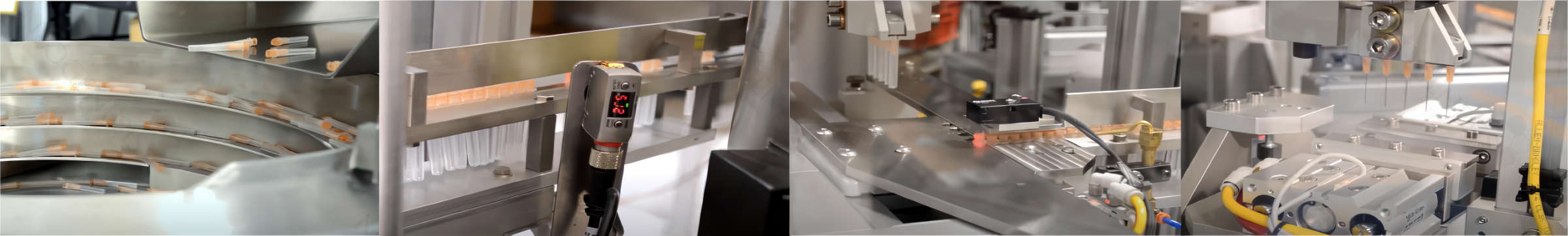

Produced in GMP Facility in Accordance to ISO Standards

Specifications, Design, and Color of the Hubs meets International Guidelines

NEO Nano Needle are produced at GMP certified facilities in compliance with ISO standards for all specifications, such as needle thickness, hub color by thickness, tip shape, and material.

4 Rules for Maximized Benefits & Safety

The Product is for Single Use Only and Unopened packaging Guarantees Sterility.

1

Be careful to pull the needle guard straight off.

2

Single Use Only.

3

Do not store at extreme temperatures and humidity.

4

Cannula of unopened or undamaged package is guaranteed sterile.

One Box contains 100EA NEO Nano Needles

Each Needle is Packaged in an Individual Sterile Pack

Neo Nano Needle

100ea / Box